Second Demo Day

News / 21.11.2019

On November 21, 2019, the outcome of the ADIR project was demonstrated at the premises of the company Electrocycling in Goslar. Since September 2015, an European consortium of nine partners has developed processes and machines for the next generation recycling of end-of-life electronics.

© Fraunhofer ILT, Aachen, Germany.On November 21, 2019, visitors had the opportunity to observe an automized piece by piece treatment of mobile phones and printed circuit boards at Electrocycling in Goslar.

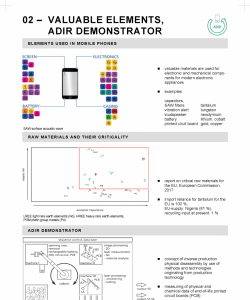

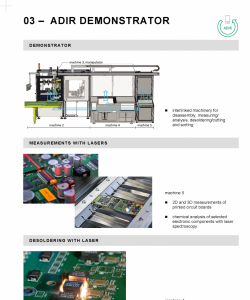

An automized piece by piece treatment of mobile phones and printed circuit boards (PCB) was shown to selectively extract valuable components such as batteries, vibration alerts, tantalum capacitors, loud speakers or any other electronic component. Besides PCBs from mobile phones, large PCBs from servers and computers with dimensions up to 500 x 500 mm2 can as well be processed. Seven machines were set-up and the visitors had a close view of their operation:

- feeding of singularized mobile phones

- disassembly of mobile phones, extraction of batteries and printed circuit boards

- manipulator to pick, to place and to transport PCBs (from mobile phones or from servers) between the various machines

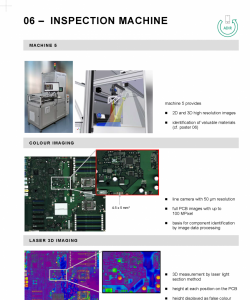

- inspection of printed circuit boards by 2D/3D imaging and laser spectroscopy to identify valuable constituents

- selective laser desoldering and cutting, sorting of extracted electronic components

- fragmentation of pre-disassembled fractions by a pulsed-power-machine for shock wave treatment

- image recognition to inspect the output fractions of the fragmentation machine to identify valuable components, such as vibration alerts

Representatives of recycling companies, research institutes, metal processing companies and telecom providers got intensive impressions of this worldwide first automated processing line for a selective physical dismantling of end-of-life electronic products.

© Fraunhofer ILT, Aachen, Germany. Taking electronic devices apart that are no longer in use to recover valuable raw materials – this is an essential objective of the EU project ADIR.