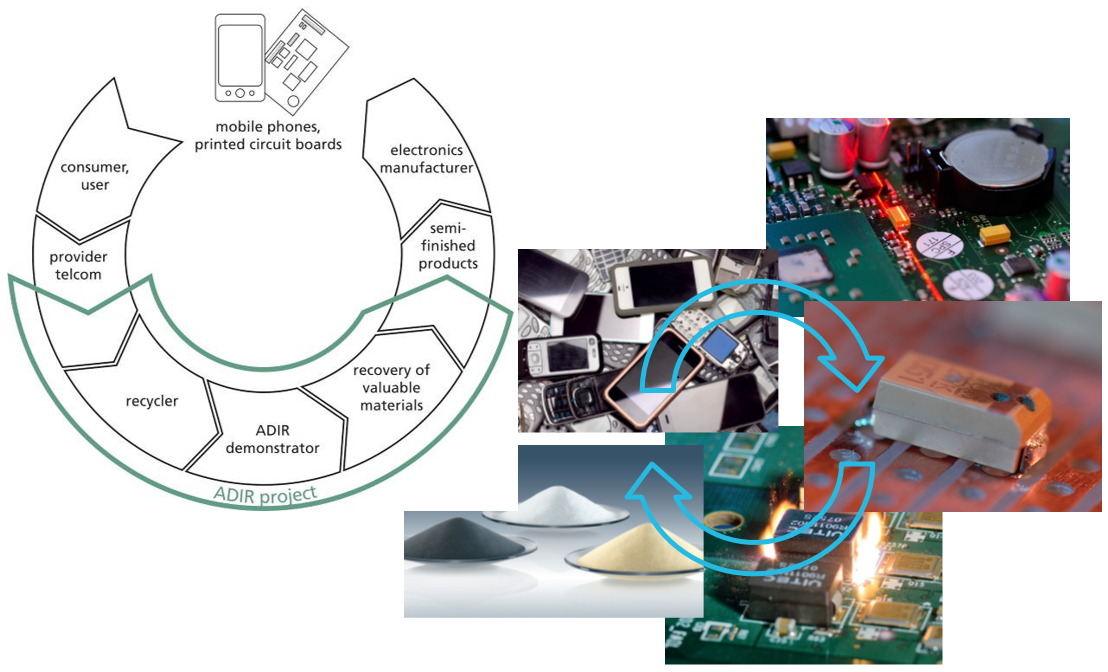

© Fraunhofer ILT, Aachen, Germany. Process chain considered in the ADIR project for a treatment of end-of-life mobile phones and printed circuit boards.

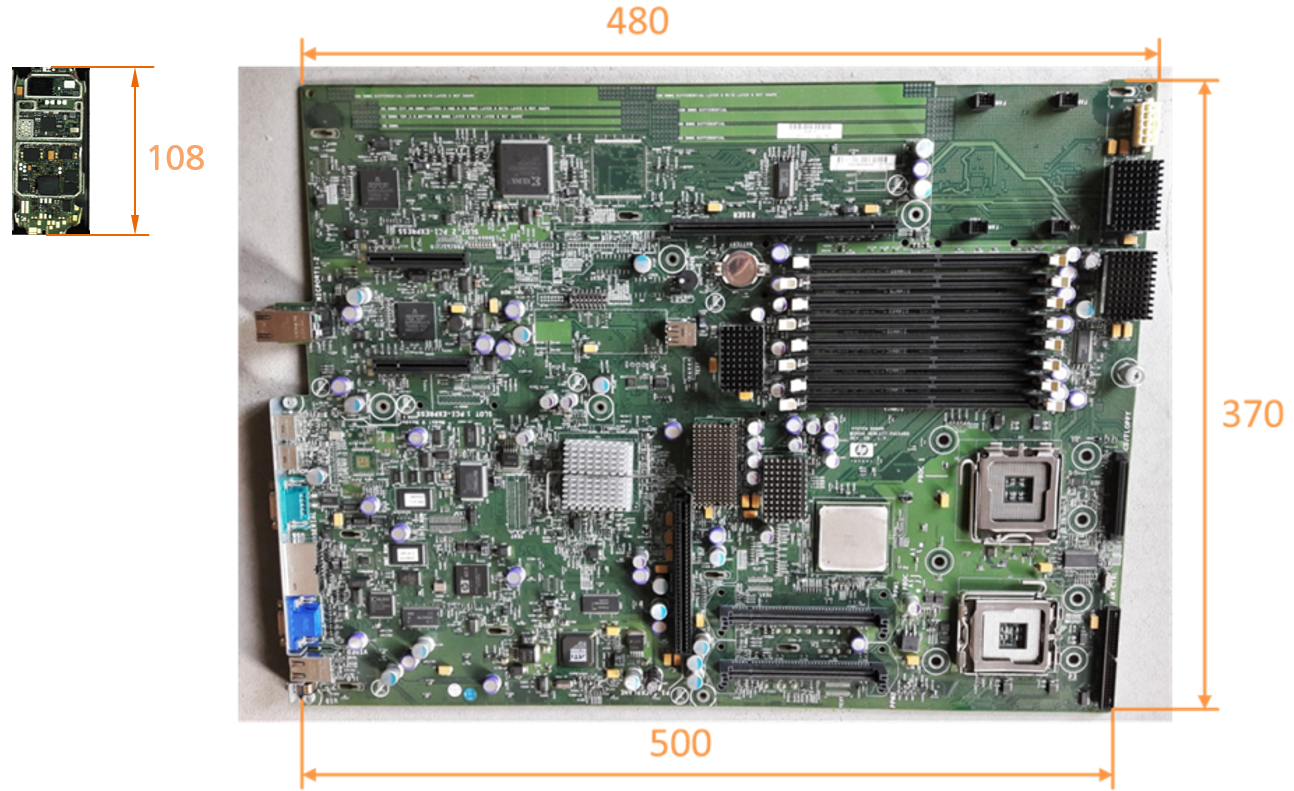

The ADIR consortium collected end-of-life mobile phones (EOL, MPHs) and printed circuit boards (PCB) from servers, studied the range of model variants, and carried out detailed chemical analyses of electronic components and modules of MPHs and PCBs using various classical analytical methods. Moreover, positions and volumes of these components are determined as a decision basis which components are of interest for a selective disassembly in terms of material value.

Older generations of MPHs as well as new generations of MPHs (smart phones) were considered. The advisory board provided recommendations with respect to the needs for the recycling line to meet both legal and environmental European requirements, to the potential for extraction of raw material as well as to parts that can be re-used. It was also agreed to prioritise material not only with economic but also environmental considerations.

© Fraunhofer ILT, Aachen, Germany. To scale images of printed circuit boards (PCB) processed in the ADIR demonstrator. Top, left: PCB from a mobile phone; right: PCB from a server. Typical dimensions are given in millimetres.

To gain a profound data basis, thirteen different models of mobile phones as exemplary samples were analysed in detail. All models were dismantled manually, the electronic components of the PCBs were extracted and analysed by a screening X-ray fluorescence (XRF) method. The complete PCBs with the electronic components were also analysed. For each of the studied MPHs a data sheet was created and documented. It contains photographic data of the disassembled phones and results of the XRF screening analysis of all electronic components, the residual bare PCB and external modules (such as vibration alert, camera etc.). Data with ranked components and modules as well as their estimated target metal contents were compiled.

Based on the determined composition of the components and the knowledge available within the consortium, preselection criteria for extraction of components were defined. In view of the economical aspect of recycling it is essential to extract the components which contain gold, palladium, silver, tantalum, tungsten and neodymium. The value of gold is about 85 % of the total value of target elements present in components dismantled from PCBs of MPHs. Based on these studies the following sorting fractions for a selective dismantling by the ADIR demonstrator were recommended: 1) all components which contain any amount of gold (Au); 2) all components which contain any amount of tantalum (Ta) and tungsten (W); 3) components which contain any amount of neodymium (Nd); 4) components which contain other target elements not covered by 1) – 3), that can be defined according to future needs.

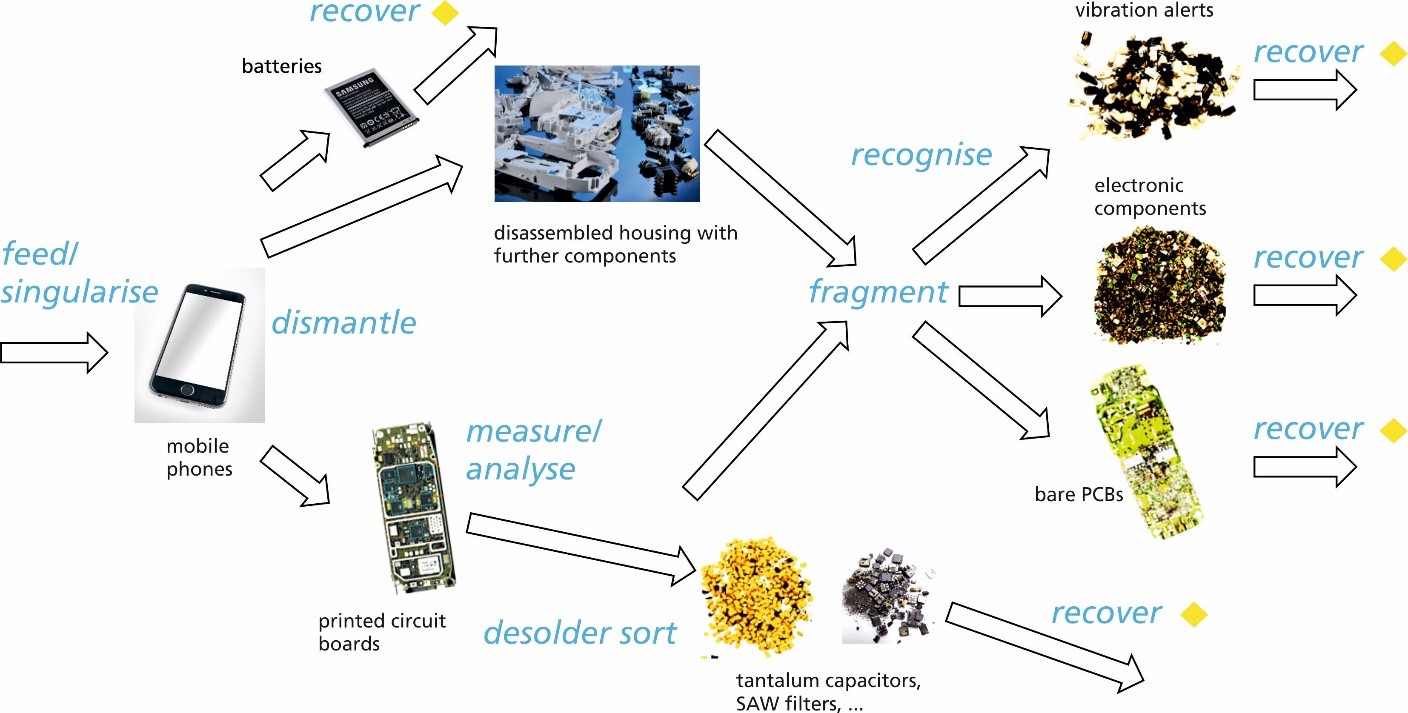

The following processes were studied and developed for a selective piece-by-piece treatment of end-of-life MPHs and PCBs and the processing of the novel sorting fractions:

- pre-sorting and singularisation of input material,

- image processing to recognise model types, orientations, positions of MPHs, PCBs,

- robotic handling of MPHs and PCBs: picking, transfer,

- dismantling actions for MPHs to extract battery and PCB,

- training of dismantling actions by test sets, working out sets of dismantling programs (model-specific sequences and processing parameter sets),

- detailed 2D- and 3D-imaging of PCBs to localise position and volume of electronic components,

- fast laser-based chemical analysis of selected electronic components to identify components with high concentrations of target elements,

- fast selective laser-based desoldering or cut out of identified electronic components,

- pulsed-power treatment of partially dismantled MPHs and PCBs to extract further valuable components such as vibration alerts, loudspeakers,

- sorting of extracted components and modules in fractions of highly enriched concentrations of target elements,

- metallurgical processes adapted to pre-concentrated novel sorting fractions.

© Fraunhofer ILT, Aachen, Germany.Process line for the piece by piece processing of a MPH. Actions labeled in blue letters are processes developed in ADIR; Yellow diamonds depict subsequent recovery routes for the obtained sorting fractions.

Based on these processes the worldwide first inverse production line comprised of seven machines was developed and set-up in a recycling plant of the consortium partner Electrocycling GmbH, in Goslar, Germany.